PATHWEL

PRODUCT

Provide products with the best quality

INNOSLIP SERIES Slip

&

Anti-Block Agents

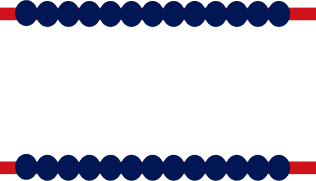

Innoslip additives are incorporated directly into the polymer during the extrusion process. They work by migrating to the surface as the polymer cools forming a solid lubricating layer at the surface. This acts to lower the friction or adhesion between contacting polymer surfaces and the polymer and other materials.

Our Innoslip line offers various grades of primary amide that can be used as slip agent, Anti-Block agent, antitacking agent and molding agent. All Innoslip products are high in purity to ensure superior performance. They are solely derived from renewable plant-based raw materials and are free from any animal products and genetically modified organisms. Our amides are also non-toxic and non-hazardous. Therefore, they are safe for a wide range of industrial applications, including the common use in food contact materials such as food wrappers, films, produce bags, bottle caps, and food containers.

In polyolefins Erucamide(or Oleamide) migrates quickly, covers the surface, has a planar layer like structure on the polymer surface. Behenamide (or Stearamide)migrates slowly, does not cover the surface so well and appears to have a more crystalline 3 dimensional structure.

The double bond in Erucamide(or Oleamide) results in poorer oxidative stability than with Behenamide(or Stearamide). Mono-unsaturates always have small quantities of poly-unsaturates which are more unstable.

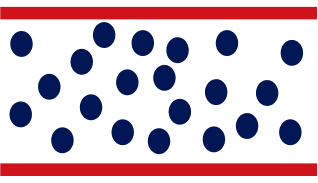

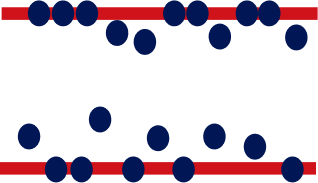

Amide is incorporated into the polymer and dispersed.

Amide is incorporated into the polymer and dispersed.

Amide is incorporated into the polymer and dispersed.

Mono-unsaturated amide

Saturated amide

• 500 ppm in LDPE film after 14 days, amide of varying carbon chain length

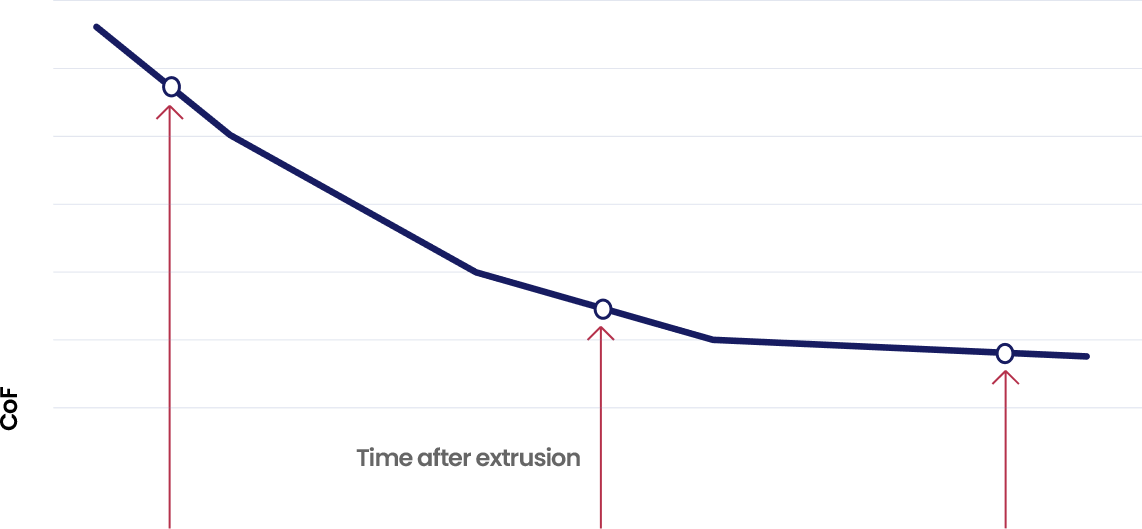

Comparative effects of amides on the slip(CoF) of LDPE vs time

- INNOSLIP-E

- INNOSLIP-O

- INNOSLIP-S

- INNOSLIP-B

Time(days)

• Comparative effects of Innoslip range on coefficient of friction in LDPE

Coefficient of Friction (CoF) at 14 days

High Slip / Secondary Anti-Block

| Trade name | Description | Physical form at 25°C | Raw material origin | Key effects & recommended uses |

|---|---|---|---|---|

| INNOSLIP-E | Erucamide | Bead / Microbead / Powder | Vegetable | Slip/release in polyolefins and many other polymers. |

| INNOSLIP-ER | Erucamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-EH | Erucamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-EL | Erucamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-O | Oleamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-ORX | Oleamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-O | Oleamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-UL | Oleamide | Bead / Microbead / Powder | Vegetable |

Low Slip & Good Anti-Block

| Trade name | Description | Physical form at 25°C | Raw material origin | Key effects & recommended uses |

|---|---|---|---|---|

| INNOSLIP-S | Stearamide | Bead / Microbead / Powder | Vegetable | Anti-Block in polyolefins, also mold release. |

| INNOSLIP-S5 | Stearamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-S6 | Stearamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-S7 | Stearamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-S9 | Stearamide | Bead / Microbead / Powder | Vegetable | |

| INNOSLIP-B | Behenamide | Bead / Microbead / Powder | Vegetable |

PATHWEL products are available in up to three physical forms

Beads

Size : 1-1.5mm Good general purpose form suitable for the majority of feeders

Microbeads

Size : 0.3-0.4mm (300-400µm) Recommended for dry mixing with other granulates

Fine powder

Size : 0.01-0.1mm (10-100µm) Recommended for dispersion into liquids or other fine powders

Polyolefin Film

Used commonly in PE and PP films, amides give slip and ant iblock properties without compromising clarity. Applicat ions include our ever yday food packaging and plastic bags, as well as agricultural films.

Masterbatch & Compound

When amides are not directly incorporated into polyolefin resins, or if an additional dosage is required, they can be added as components of masterbatches and compounds to suit the needs of the end user.

Paint, Ink & Dye

In paint, ink and dye, amides can serve as pigment dispersing aids and also as thixotropic agents to increase product viscosity.

Molding

In both injection and rotational molding processes. Amides can serve as a mold release agent. They also improve the product surface finishing and add a scuff resistant property, thus reducing wastage and product defect.

Lubricant

Our sl ip agent s , namely oleamide, can be used in lubrication oils and greases to enhance their friction reducing performance. They can also be used to control viscosity.

Rubber

Not only do amides serve as internal lubricants that facilitate rubber processing, they also serve as dispersing aids for pigments (e.g. carbon black). They are also used as a release agent in rubber molding operations.